Process Engineering and Power-to-X processes

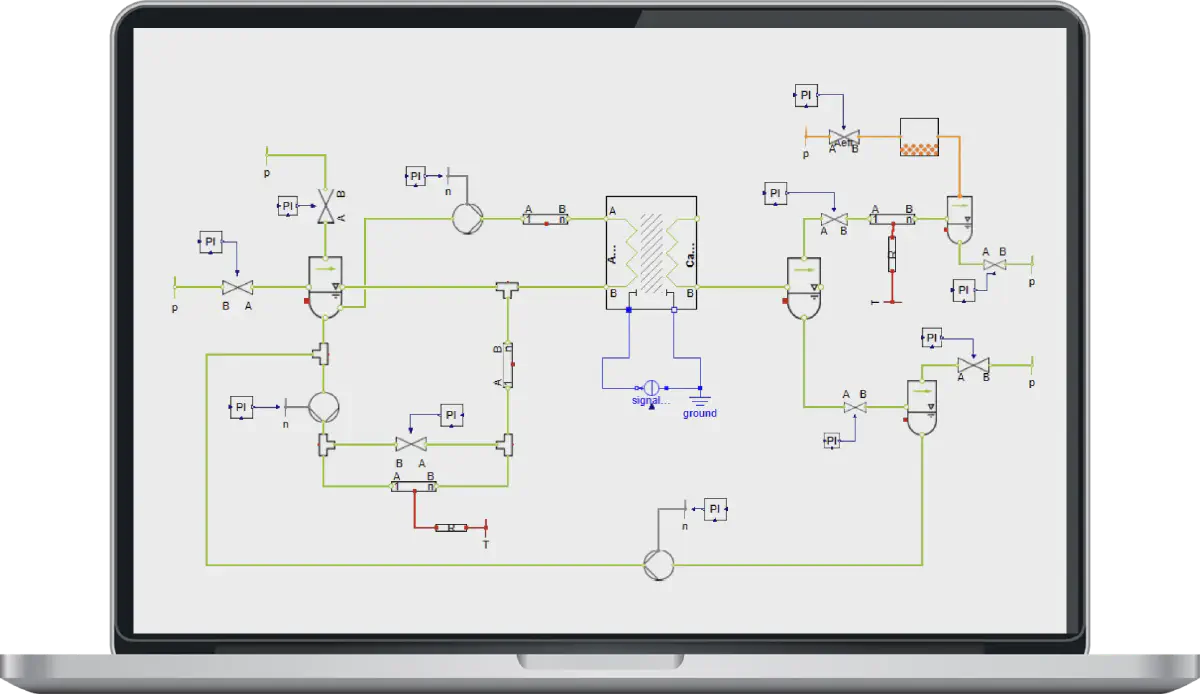

The Process Systems Library by TLK Energy GmbH is the only commercially supported Modelica Library fully dedicated to process engineering. The library provides a wide range of models for general process engineering simulation, but has its focus on transient simulation of Power-to-X processes. The challenge in the Power industry today is primarily to cope with fluctuations of renewable energy production. Traditional, steady-state design tools for such processes are therefore inadequate to capture the true value proposition of Power-to-X processes. This is where the intrinsically dynamic nature of Modelica models show its greatest advantage: transient behaviour can be considered already in early design phases. Costly changes late in the design process are thus avoided.

The open code makes it easy for you to look at and understand the equations. It also makes it straight-forward to adapt to your own needs, and keep your core, product-specific IP private to your team.

Thanks to the modular, object-oriented structure, you can flexibly reuse models. This works hand-in-hand with the open code to combine flexibility with easy of use.

Combine models from with models from PSL with any other Modelica libraries, such as the TIL Library, and libraries from other domains for full system simulation.

Interested in Modeling Power-to_X processes? Or integrate Process systems in a larger context?

While there are many options to model process systems by themselves, Modleica-based solutions stand out in at least two different aspects:

- Modelica tools and libraries tend to be more robust and versatile than classical process engineering tools for dynamic simulation, whenever chemical process need to be integrated with e.g. electrical loads, run in islanding mode, and run more dynamically than traditional chemical plants.

- In addition, the Modelica Association open standards make it much more straightforward to integrate the solution into digital twins, for advanced control, predictive maintenance, or simply improved remote monitoring, with a much better understanding of the remote plants performance than with just sensor-based remote monitoring.